מחרטה ידנית Unimat ML תוצרת אוסטריה לימודית

קרא עוד

Unimat ML

160200

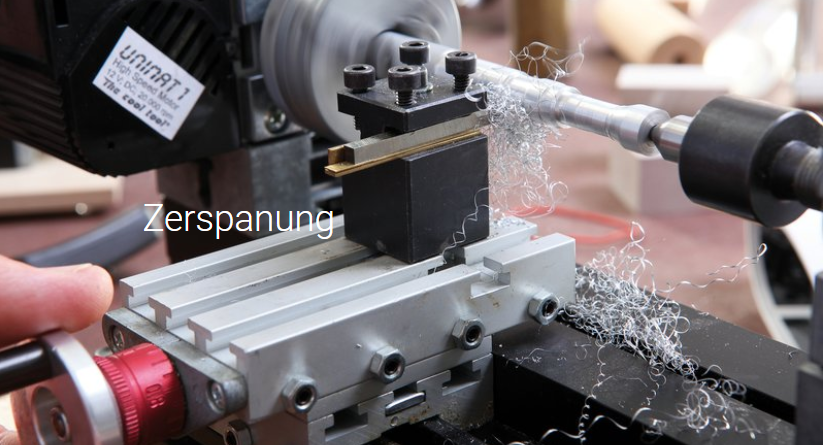

Slides, tailstock and intermediate pieces are composed of metal, manufactured and processed on cutting-edge CNC machines for perfect alignment. This guarantees a high level of precision despite the modularity of all machines. The UNIMAT MetalLine excels in model making, technical education, as well as in industrial use with features like:

enhanced stability and precision of the entire system

modular structure and easy handling

lowest tolerances due to precisely fitting bearing seats

true-running accuracy through dust protected industrial ball bearings

adjustable dovetail guides

flat milled, grinded and matched components

increased wall thickness of the profiles (torsion resistant and stable)

metal zero-adjustable hand wheels (0.05mm scale)

|  |

|  |

Technical Data

Motor | 20.000 rpm, 12 VDC |

Headstock | M12x1, 8 mm hole through spindle |

Gear ration | 1:5 (4000 rpm) |

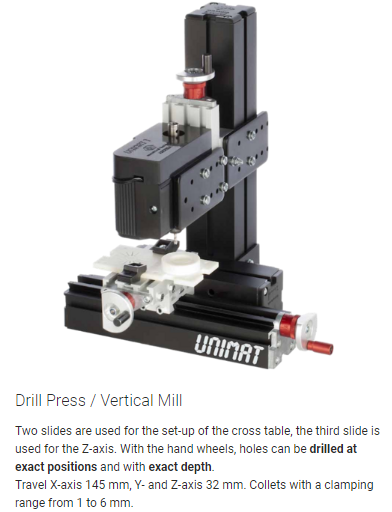

Slides (Travels) | 2 cross slides (30 mm), 1 long slide (40 mm), screw pitch 1 mm |

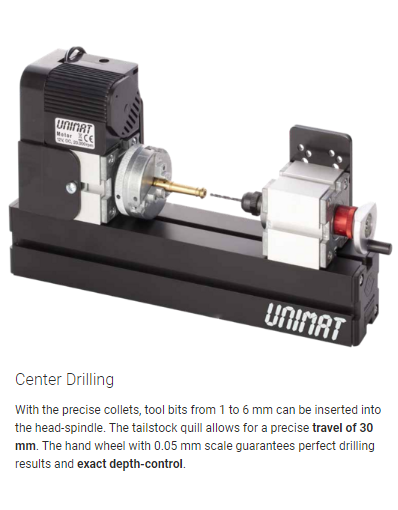

Tailstock | M12x1, 30 mm quill travel |

3-Jaw-Chuck | Clamping capacity 1.8-56 mm inside, 12-65 mm outside |

Adaptor | 110-240V/50-60Hz,12V DC, 2A |

|

|

|